5083 Aluminum Sheet

- Home

- 5083 Aluminum Sheet

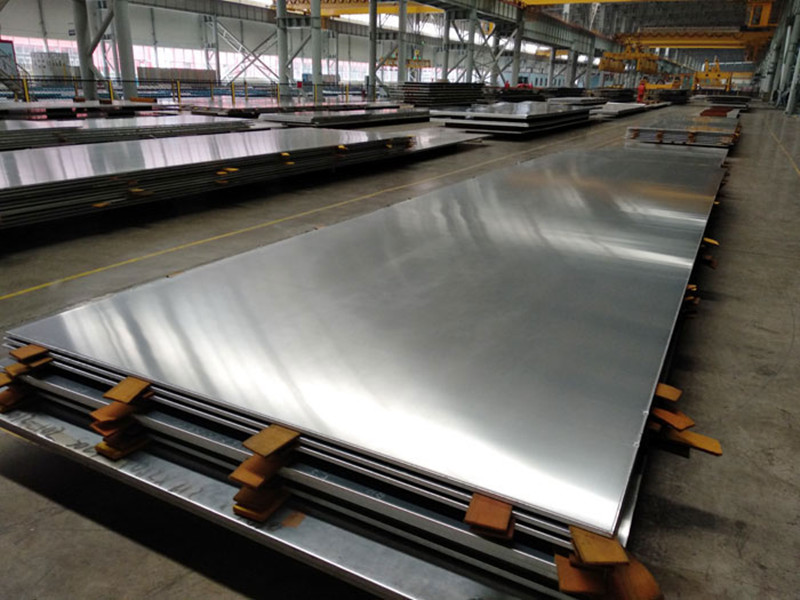

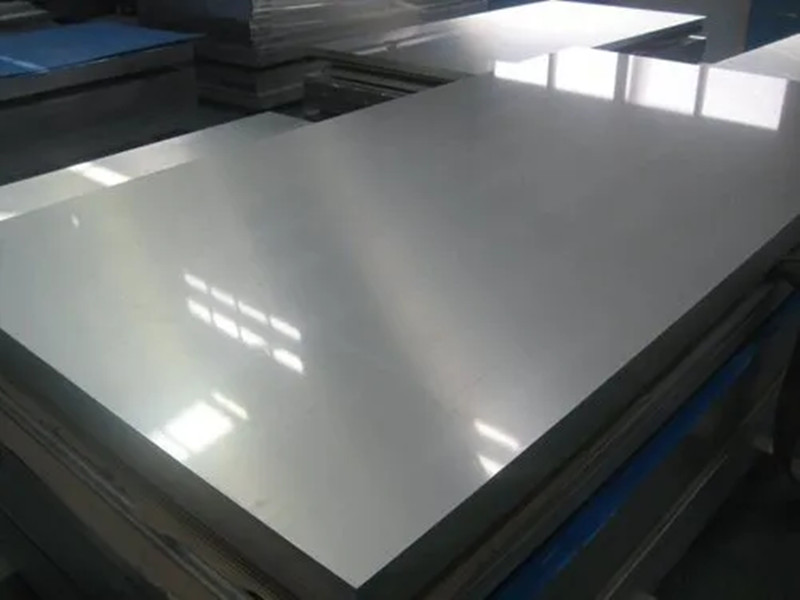

5083 aluminum sheet belongs to the Al-Mg series alloy, which is widely used, especially in the construction industry, which is the most promising alloy. Good corrosion resistance, excellent weld-ability, good cold work-ability, and moderate strength. The main alloy element of 5083 is magnesium, with good form-ability, corrosion resistance, weld-ability, medium strength, used in the manufacture of aircraft fuel tanks, oil pipes, and traffic vehicles, ships of sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical shell and so on.

Specification

- 5083-H116 Aluminum Sheet 0.125″

- 5083-H116 Aluminum Sheet 4.0 mm / 0.160″

- 5083-H116 Aluminum Sheet 0.190″

- 5083-H116 Aluminum Sheet 5.0 mm / 0.197″

- 5083-H321 Aluminum Sheet 0.125″

Mechanical properties

Tensile strength (MPa) : 110-136

Elongation (%) : ≥20

Annealing temperature: 415℃.

Yield strength (MPa) ≥110

Specimen blank dimensions all wall thicknesses

Elongation (%) ≥12

Application

5083 aluminum plate is commonly used in

- Ships

- Vehicle materials

- Automobile

- Aircraft plate welding parts

- Pressure vessels

- Refrigeration devices

- TV towers

- Drilling equipment

- Transportation equipment

- Missile components, armor and so on.

Chemical Composition

Chromium: 0.05%-0.25%

Copper: 0.1%

Magnesium: 4.0%-4.9%

Manganese: 0.4%-1.0%

Silicon: 0.4%

Zinc: 0.25%

Aluminum: 92.4%-95.6%

5083 Anodize Aluminum

5083 is a magnesium alloy with good strength, corrosion and mach-inability in non-heat treatment alloys. Beautiful surface after anodizing. Good arc welding performance. The main alloying element in 5083 alloy is magnesium, which has good corrosion resistance and weld-ability, as well as moderate strength. The excellent corrosion resistance makes 5083 alloy widely used in maritime applications such as ships, as well as automobiles, aircraft welding parts, subway light rail, pressure vessels requiring strict fire protection (such as liquid tank trucks, refrigerated trucks, refrigerated containers)and etc.

3003 Aluminum sheet

3003 is AL-Mn alloy, is the most widely used a kind of anti-rust aluminum, the strength of this alloy is not high (slightly higher than industrial pure aluminum), can not be strengthened by heat treatment, so the use of cold processing method to improve its mechanical properties: In the annealing state has a high plasticity, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weld-ability, poor mach-inability.

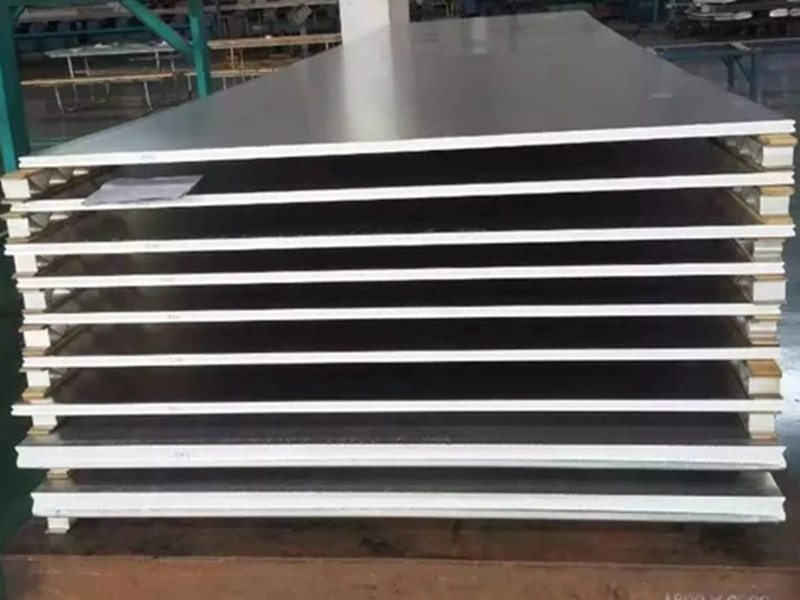

5083 Aluminum sheet factory

Henan Worthwill Industry Co., Ltd is the international sales company of Henan Jinyu

Color Aluminum Co., Ltd. Our Factory is located in the Industrial Park of Huiguo Town,

Gongyi, Zhengzhou, China, which is nearby Gongyi Nan High Speed Railway Station and

G310 State Road with a convenient transportation.

Our company is a private Joint-stock Company, registered Capital by 50,000,000 CNY,

covers an area of 80,000 square meters with more than 200 employees, including more than

30 technical and management personnel. We are led by technological innovation, integrated

on Scientific Research, Marketing and Production, supported by Henan Provincial Commerce

Department as an Export-Oriented enterprise. Our main products are 5083 aluminum sheet aluminum color coating sheet/coil, curtain wall panel, wooden grain and marble coated products.