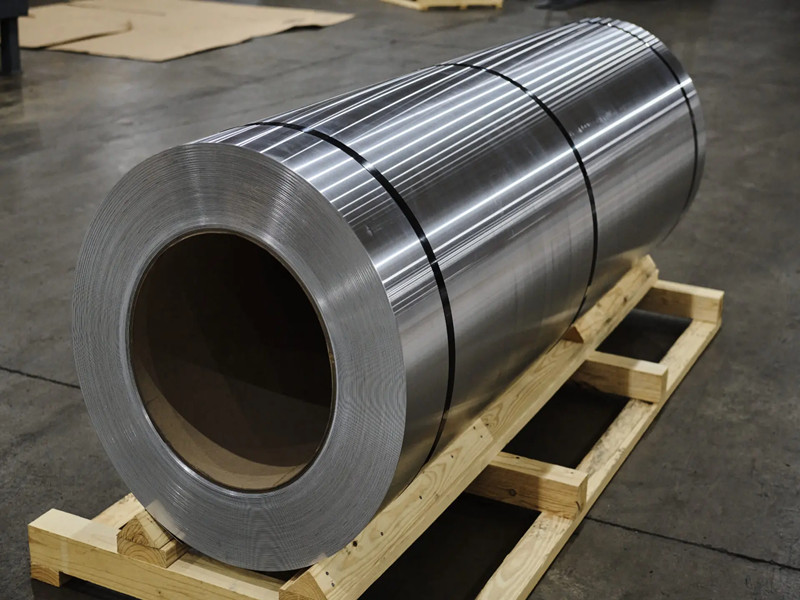

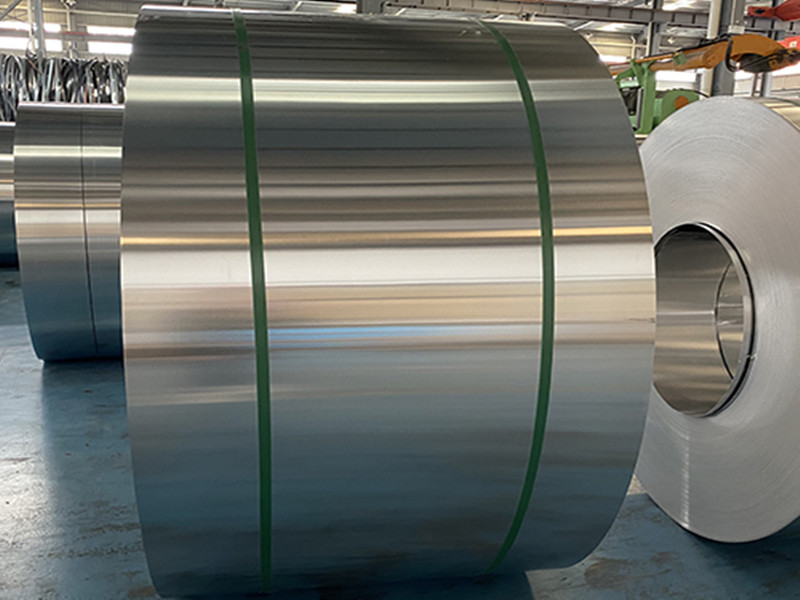

Aluminum Coil

- Home

- Aluminum Coil

Aluminum coil is a key component in the construction of many types of buildings. From residential and commercial to industrial and public facilities, aluminium coil helps to create a variety of different products that building designers need.

Specification

| Width(mm) | Length(mm | Surface | MOQ(tons) | Package | Alloy |

| 30-1650 | customized | smooth | 5 | Standard sea worthy package | 1000,3000,5000 |

The Features and Applications of Aluminum Coil

1000 Series Aluminum Coil Feature

Low strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. The workability of 1000 series is the highest among commercial aluminum alloy. Readily to welding, brazing, and soldering. Machinability is poor and tends to be “gummy”. Non-heat treatable.

1000 Series Aluminum Coil Applications

This seriesl has a usage in processing parts which require good forming property and high anti-corrosion, but do not require high strength, such as chemical products, devices and storage containers used in the food industry, heat exchangers, welding parts, etc.

3000 Coil Features

This series is anticorrosive and its production technology is good. The main ingredient in it is manganese element and the content is between 1.0% and 1.5%.

3000 Coil Applications

As a result of its good property in anti-corrosion, this series has a common use in moist environments like air conditioners, refrigerators, at the bottom of cars, etc.

3000 series aluminum coils is 20% stronger than the 1000 series, has great workability. The 3000 series aluminum coil is widely used for general purposes. 3003 Aluminum coil Approx 20% higher strength than the 1100 series, but retaining an excellent workability rating. May show some slight discoloration when anodized, but reacts well to mechanical and organic finishings. 3003 has good welding performance. Like 1100, tends to be “gummy” when machined. Non-heat treatable.Typical applications include food and chemical equipment, appliance components, truck and trailer roofing, heat exchangers, and lawn furniture components.

5000 Coil Features

The main ingredient of this series is magnesium element and the content is between 3% and 5%. With its low density, it features high tensile strength and elongation.

5000 Coil Applications

With the same area of other series, the weight is lighter. As a result, it is used in aviation, such as in the fuel tanks in airplanes. It has a wide use in conventional industries.

This aluminum coil can be used in continuously casting and rolling. It can be hot rolled. As a result, it can be used in oxidation and deep processing.

What is Aluminum Coil Made of?

The aluminium coil that we’re accustomed to using is a product created by rolling an aluminium sheet. It’s no ordinary roll—the diameter of the roll is larger than the width of the finished product, so we’re talking about some seriously oversized rolls.

Since you can’t weld or join two pieces together, those massive rolls would be worthless unless you could find a way to get those flat surfaces back into a cylinder shape. Enter the spindle pickle line and its ability to produce very precise shapes out of relatively large materials.

Supplier

WORTHWILL is professional in producing aluminum coils. The coils from our company have top quality and competitive price. Our company not only a manufacturer, but also an exporter. And we have done business in foreign market about eight years. In addition, our company has received lots of good feedback from customers. Many of them want to built long-term cooperative relationship with us. WORTHWILL supplies the most extensive aluminum corrugated sheet. If you have demand, please feel free to contact us. More information please browse our website.