Aluminum Foil

- Home

- Aluminum Foil

Aluminum foil is an aluminum alloy product with excellent electrical and thermal conductivity. It is very thin, usually no more than 0.2 mm thick, with strong ductility, toughness and protection characteristics. Aluminum foil has excellent material properties, can withstand various pressures and shape changes, and has a wide use in many different fields.

Advantages of Aluminum foil

1.Good corrosion resistance: The surface of the aluminium foil is covered with an oxide layer, which can improve its corrosion resistance and extend its service life.

2.Strong thermal insulation performance: The surface covering layer can not only protect the metal itself from oxidation, but also form the effect of heat insulation and prevent the loss of internal temperature.

3.Good plasticity: As a very thin metal product, aluminium foil has strong ductility and plasticity, and can withstand various shapes and be as a container.

Specification diversification: Aluminium foil has a very wide range of specifications,thickness, width, length can be adjusted to meet a variety of different needs.

Specification

| Product | Temper | Width | Thickness | Protection | Package | MOQ |

| Aluminum foil | O, H18, H22, etc | 150-1250mm or as request | 0.005-0.2mm as request | PE protective film as request | Standard seaworthy exporting packing | 3 tons |

Application of Aluminum Foil

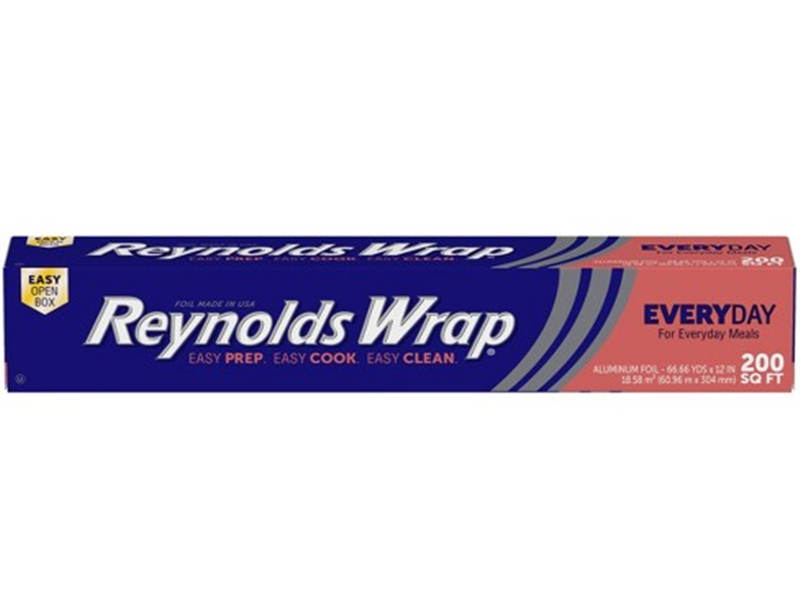

- Packaging

Food and pharmaceutical industries are the common use. As a mixture of viscose paper and plastic bags, it can effectively protect internal products such as food, medicine and cosmetics and prevent external oxidation and pollution. In addition, it has uses in blister container and plastic wrap for a higher degree of protection.

- Kitchen

As a kitchen accessory, aluminum foil has a very wide range of uses, such as:

Packaging: Used to package oil, meat, seafood, vegetables and other ingredients, to prevent oxidation and preservation.

Cooking: used to wrap ingredients and make cooking delicacies such as pot wrapped meat and grilled fish

Oven pan: Use aluminum foil to make oven pan, easy to clean and use.

- Electronic product

Aluminum foil also plays an important role in the field of electronics. It can be as a covering material for the circuit board to protect the board from electromagnetic interference and temperature increase. And electrodes in electronic devices such as capacitors, inductors and electrolytic capacitors.

Classification and Types of Aluminum Foil

Classification

1.Foil thickness

Heavy gauge foil: 0.1-0.2mm

Medium gauge foil: T=0.01mm, T<0.1 mm

Light gauge foil: 0.005-0.009mm

2.Aluminum alloy: We all know that aluminum alloy has eight series. We also can divide the aluminium foil into eight series.There are some common alloy such as:

1 series: 1050, 1060, 1070, 1100

3 series: 3003, 3004

8 series: 8011

Types

In our company, we produce many kinds of alu foil to apply to different fields.

Household Foil: 8011, 0.009-0.02mm

Container Foil: 8011/3003, H22/H24,0.03-0.09mm

Pharmaceutical Foil: 8011/8021, O/H18,0.018-0.08mm

Hydrophilic Foil: 8011, O/H22, 0.08-0.16mm

Flexible package foil: 8011/8079, O/H22, 0.06-0.2mm

Air duct foil: 8011, O, 0.06-0.15mm

Cigarette foil: 1235/8079, 0.005-0.008mm

Cable foil: 1100/1145/1235/8011, O,0.1-0.2mm

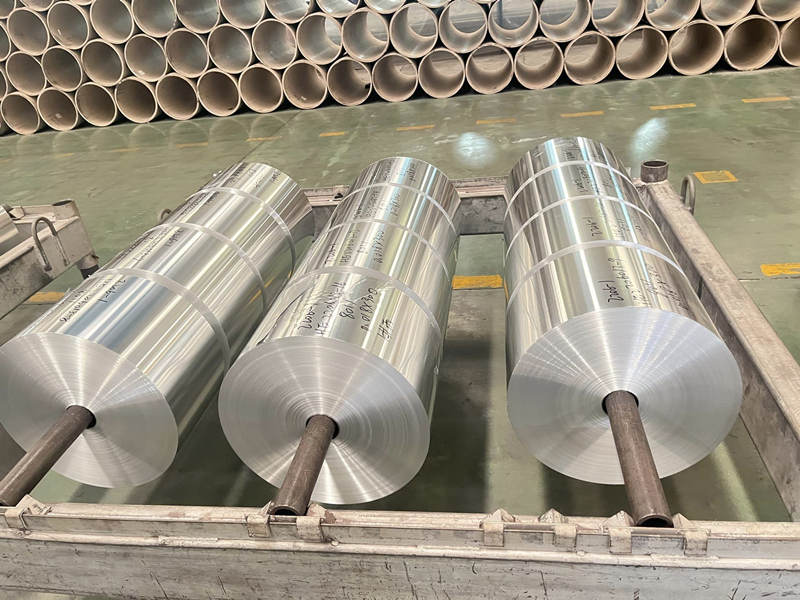

The Process Line Of Aluminum Foil

The making of aluminium foil is similar to making pasta at home. The sheet is coiled on a roll and sent to a cold rolling mill for rolling. Rolling reduces the thickness of the aluminium block and spreads it out. The side of the aluminium in contact with the steel roll becomes smoother and glossier, and the aluminum in contact with itself becomes matte. Lubricants are added during rolling to facilitate operation. With each successive pass through the roll, the thickness is continuously reduced. Repeat the process until you reach the foil thickness, then cut the large foil to the desired width.