Coated Aluminum

- Home

- Coated Aluminum

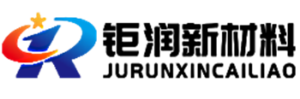

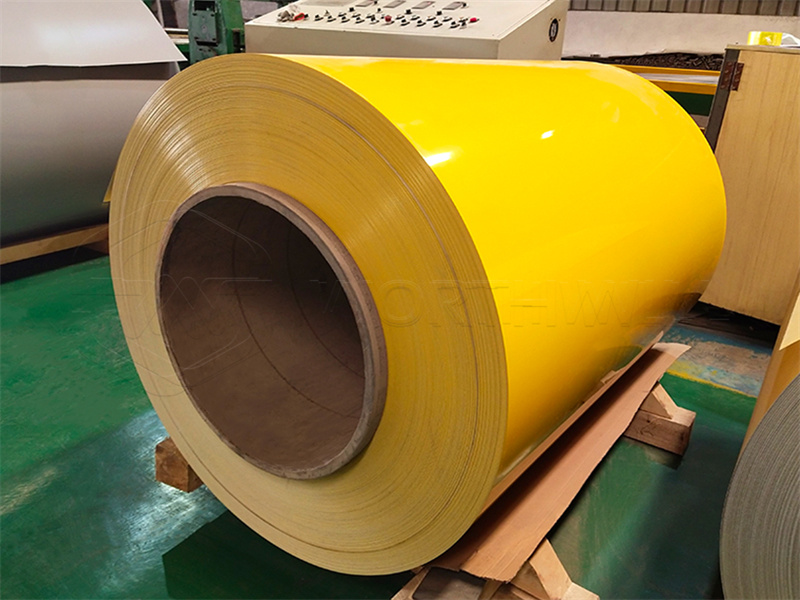

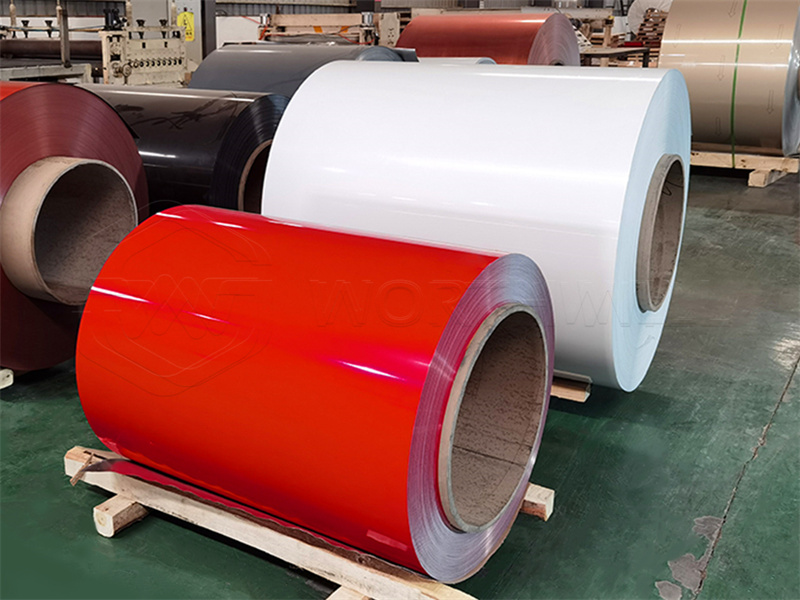

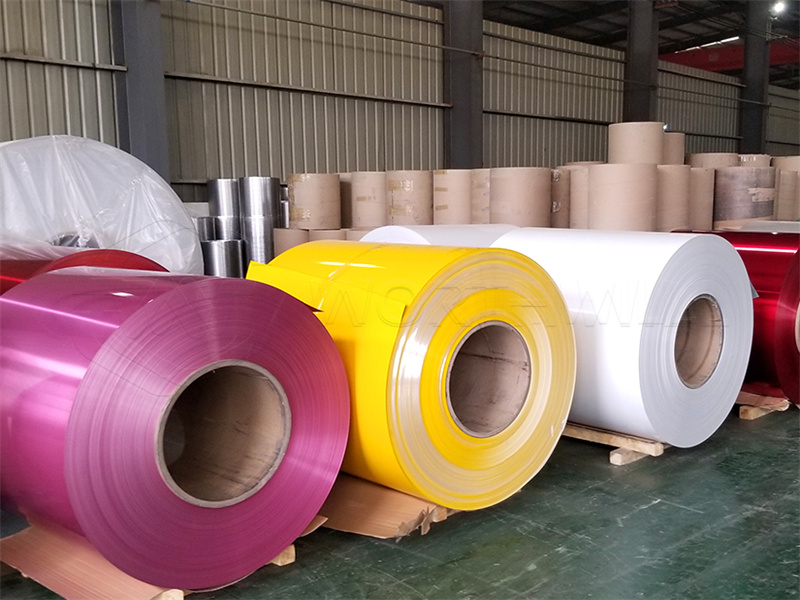

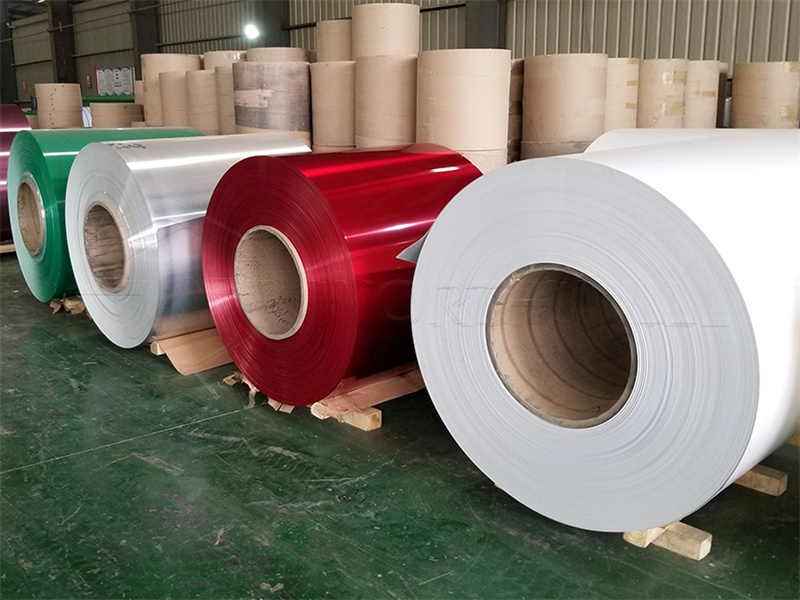

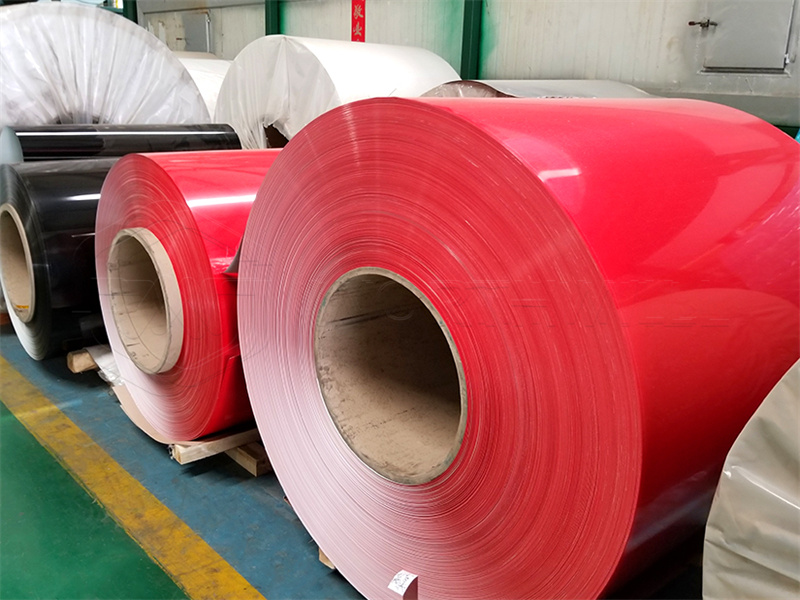

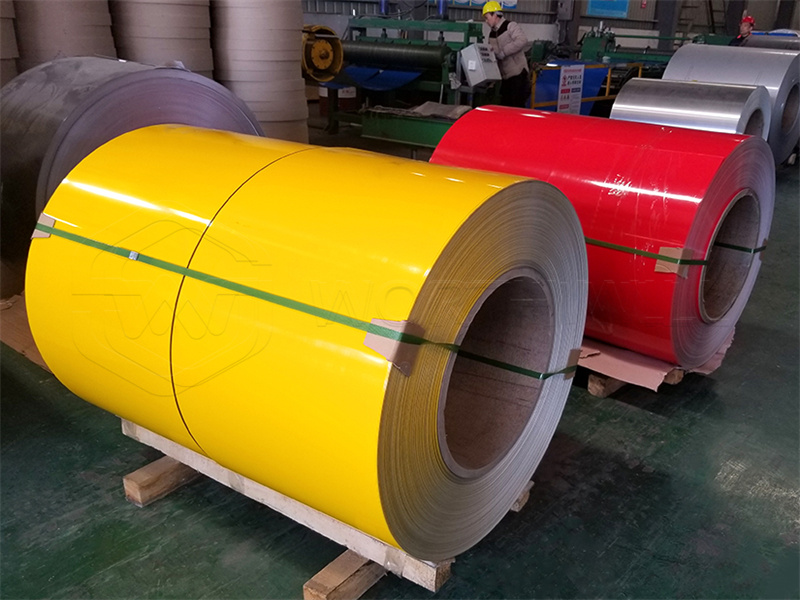

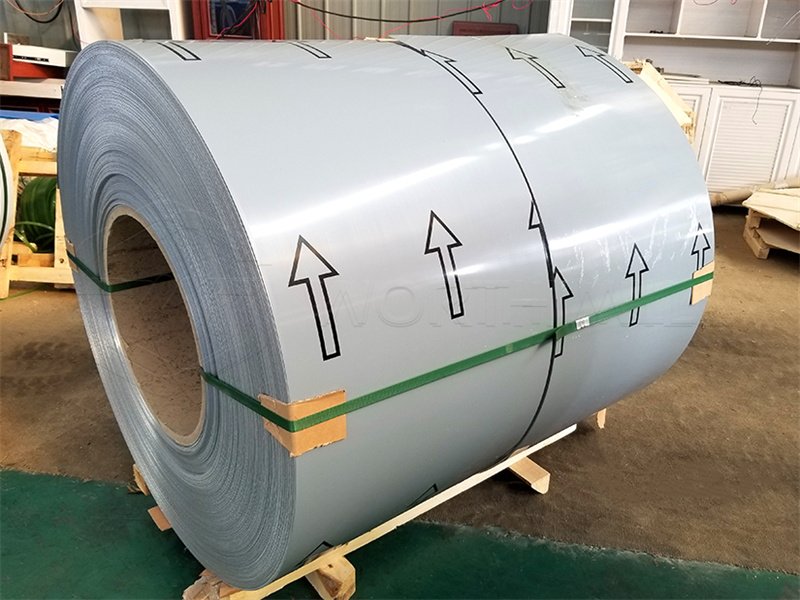

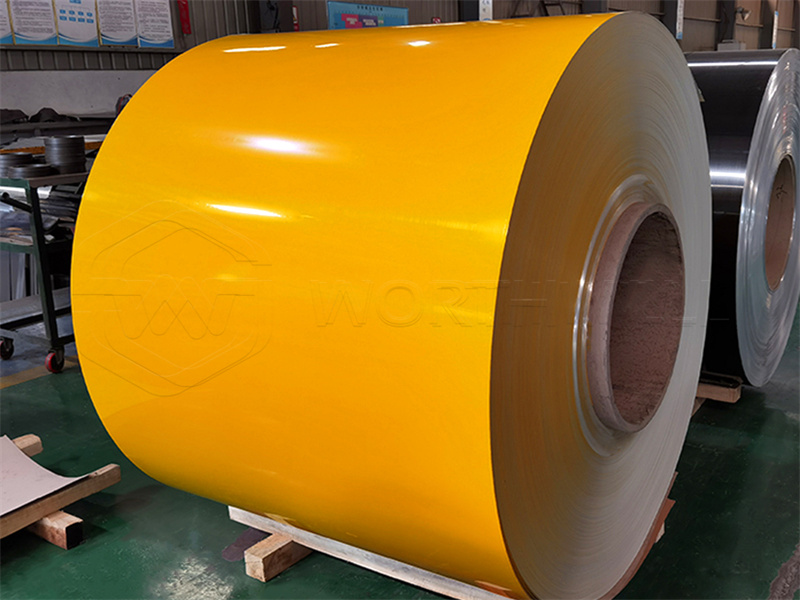

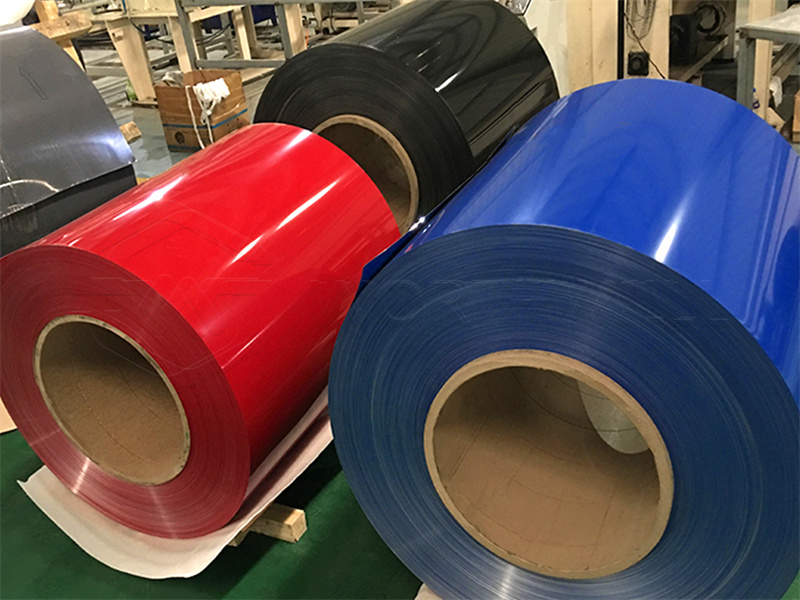

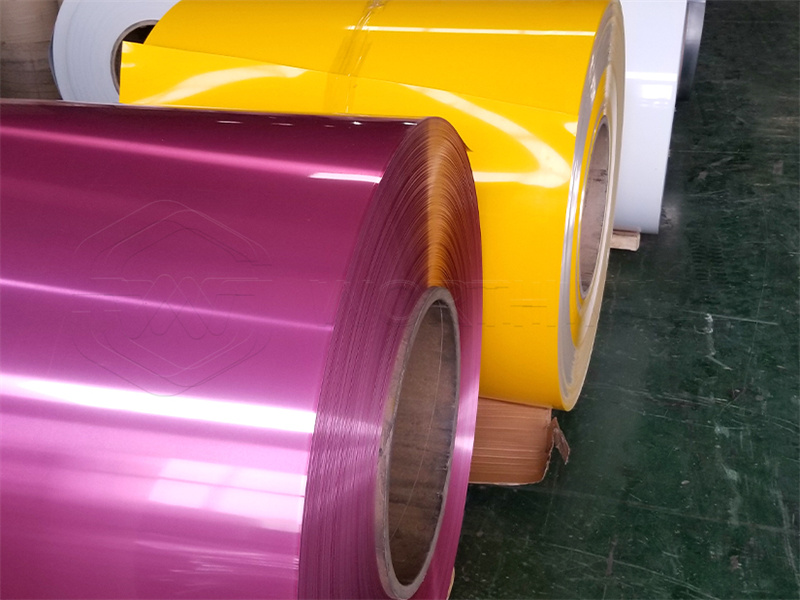

Coated aluminum refers to the surface of aluminum alloy coloring treatment, because the performance of aluminum alloy is very stable, so it has good corrosion and long shelf life of 30 years. But also because of its small density, high hardness, the weight per unit volume is the lightest metal material. Color aluminum is the latest rise in the field of doors and windows of a new profile, compared with plastic steel, the biggest advantage is that the degree of robustness is unparalleled, and the color is changeable, and always will not face plastic steel is always with a “toxic” word. The common product of coated aluminum are Fluorocarbon color coated aluminum(PVDF) and polyester color coated aluminum(PE).

Specification

| Product name | Alloy | Temper | Color | MOQ |

| Coated aluminum | 1xxx,3xxx,5xxx series | H14/H18/H24 | Black, white, red, brushed gold, mirror silver, imitation wooden, etc. | 2-4tons |

Applications

It has a wide usage, such as aluminum composite panel, aluminum veneer, aluminum honeycomb panel, aluminum ceiling, roof surface, leftover material, cans, electronic products etc.

Advantages

- Most light

- No rust

- Stable performance

- Durable

- Good color

- Good weather

- High quality

- Good ductility

Classification of coated aluminum coil and sheet

According to the thickness of the coating, there are three specifications

- Single-coated :4-20microns

- Double-coated:25-28microns

- Triply-coated:35-38microns

The Coating Processing Line

- Put the plain coils in the decoiling machine and let it trough the Material storage tower.(To prevent turn off the whole processing line when we change new coil)

- Pre-processing. Firstly through the alkaline water tank to degrease the coil,secondly use the tap water to clean, then the acid to neutralize the remnant alkali, at last completely clean with pure water.

- (the temperature is 210-230 degree Celsius.

- Add the chromium to passivate the coil and enhance the adhesive strength.

- Coat the bottom of the coils with clear varnish or white and gray paint.

- Drying.

- Use air cooling system or water cooling system to cool them down.

- drying again.(water cooling system)

- According to customers’ requirement to make second coating.

- Drying.

- Covering the surface of coils with plastic film.

- Packaging with inner paper tube about 15-20mm in thickness

- Sending them to the storage.

What is PE Coated Aluminum?

PE coated aluminum is a sustainable material that can contribute to green building practices. It is fully recyclable, and indefinitely without losing its properties. And the material is low in VOC emissions. So it can reduces the environmental impact of building construction.

What is PVDF Coated Aluminum?

Fluorocarbon (PVDF) coated aluminum, the literary name of polyvinylidene fluoride color-coated sheet. It is made of advanced polyvinylidene fluoride resin. There is a strong bond energy between the chemical bond and chemical bond of PVDF, so the coating has very good corrosion resistance and color retention. Among the coated aluminum coatings for the construction industry, it is a high-class product with a large molecular weight straight bond structure, so in addition to chemical resistance, mechanical properties, UV resistance and heat resistance are also outstanding. Under normal circumstances, the anti-corrosion period of the base can be as long as 20-25 years.

The difference between PE and PVDF Coated Aluminum

- The polyestercoating has different applications indoors and guaranteed for 10 years. Fluorocarbon coatings has applciation in outdoors and guaranteed for 15-20 years.

- Only single coated and double coated polyester coating, fluorocarbon coating including double coated and three with.

- Polyester coatingis cheap, and fluorocarbon coating price expensive.

- Polyester coating used for coil, fluorocarbon coating forsheet more.

- Polyester coating are common on the market, the price is cheap.

- PE coating high gloss, can achieve 90% above PE coatingcan only single or double coated, coating is too thin shelf life is very short, coating is too thick easy to agglomerate.

Coated aluminum supplier

Our company is business in aluminum color coating coil for 10 years. We have our own factory,so we can provide factory price and good quality. We have many export experiences to other country, and we are the gold supplier of the aluminum coated coil. Many of our customers are satisfied with our products.